Difference between revisions of "iMX8M Industrial EMC testing"

| Line 7: | Line 7: | ||

These tests were performed with setups using the actual hardware and software configurations of the web shop development kits. | These tests were performed with setups using the actual hardware and software configurations of the web shop development kits. | ||

| − | These measurements were performed in an accredited test laboratory. After passing all the requirements described in the standard ETSI EN 301 489-17, the [https://downloads.voipac.com/files/iMX8M_Industrial_Development_Kit/module/documents/EMC_certification/iMX8M_Industrial_Development_Kit-EMC_certificate_with_conformity_assessment_and_test_reports.pdf EMC certificate with conformity assessment and test reports] was granted to the iMX8M Industrial Development Kit. | + | These measurements were performed in an accredited test laboratory. After passing all the requirements described in the harmonised standard ETSI EN 301 489-17, the [https://downloads.voipac.com/files/iMX8M_Industrial_Development_Kit/module/documents/EMC_certification/iMX8M_Industrial_Development_Kit-EMC_certificate_with_conformity_assessment_and_test_reports.pdf EMC certificate with conformity assessment and test reports] was granted to the iMX8M Industrial Development Kit. |

== Connected cables/devices == | == Connected cables/devices == | ||

Revision as of 13:55, 31 March 2023

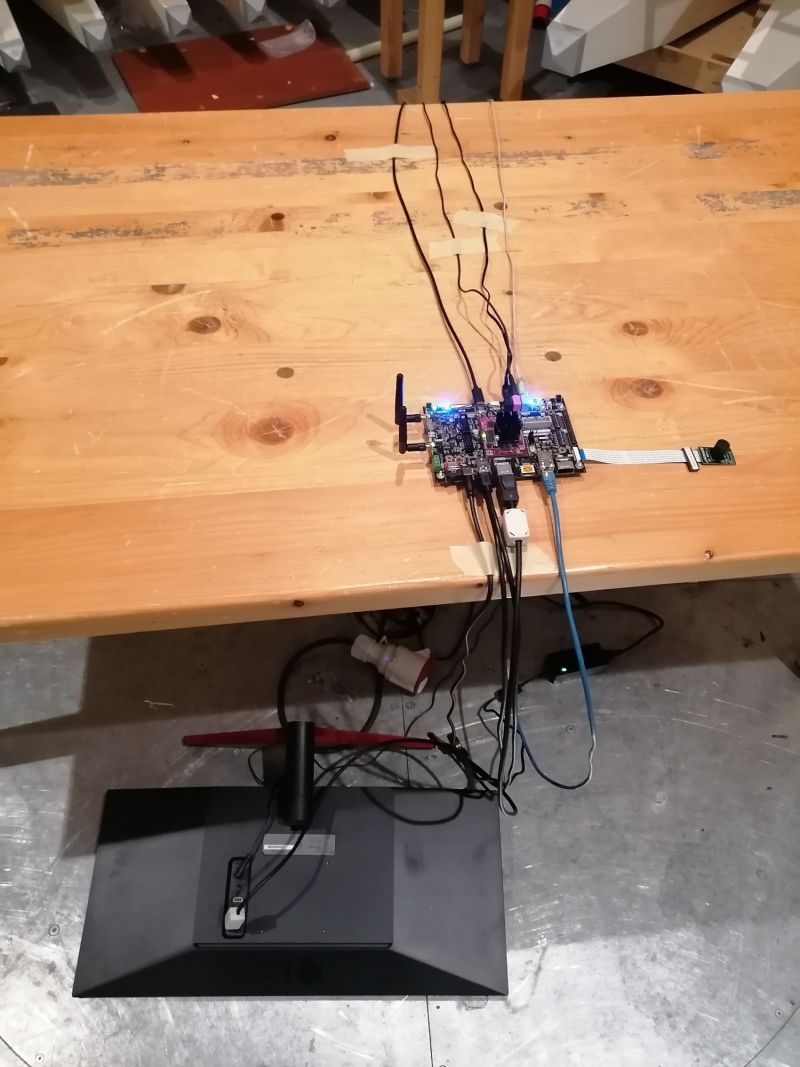

Electromagnetic compatibility results for iMX8M Industrial Development Kit are presented on this page. Test setup and scripts are described in details.

These tests were performed with setups using the actual hardware and software configurations of the web shop development kits.

These measurements were performed in an accredited test laboratory. After passing all the requirements described in the harmonised standard ETSI EN 301 489-17, the EMC certificate with conformity assessment and test reports was granted to the iMX8M Industrial Development Kit.

Connected cables/devices

- Power source: +5V 40W power supply used for input voltage

- Storage device: eMMC Flash memory soldered on module used for booting, filesystem operation and script storage

- Ethernet: 1m long CAT Ethernet loopback cable connected. Forced to 100Mbps and used for ping test

- one of these video output options was used at a time:

- DisplayPort (M) interface used with LCD monitor connected: Full-HD output video stream generated and sent to LCD monitor via 1.5m long DisplayPort cable, with ferrite beads added (P/N: Würth Elektronik 742 711 32). The output signal forced to be continuously generated, contributing to EMC spectrum, monitor was plugged into mains, turned on, and laid flat on the floor to minimise its affect on results. Used LCD monitor: 24" LG LG24BK550Y 1920×1080 px

- HDMI interface used with LCD monitor connected: Full-HD output video stream generated and sent to LCD monitor via 1.5m long HDMI cable, with ferrite beads added (P/N: Würth Elektronik 742 758 15). The output signal forced to be continuously generated, contributing to EMC spectrum, monitor was plugged into mains, turned on, and laid flat on the floor to minimise its affect on results. Used LCD monitor: 24" LG LG24BK550Y 1920×1080 px

- LCD Display: Newhaven LVDS Capacitive Display Set with 1024x600 resolution. LCD P/N: NHD-10.1-1024600MB-LSXV-CTP

- 2x USB 3.0: SanDisk Ultra Flair 16GB USB 3.2 Gen 1, each connected through a 1m long USB 3.2 Gen 1 extension cable (Molex P/N: 0687890035). Both used during read/write test

- USB-C: Kingston DataTraveler 80 32GB USB 3.2 Gen 1, connected through USB-C extension cable (Cable P/N: FCR72003)

- Camera: Digilent MIPI-CSI Camera Set plugged to the baseboard, recognised by the kernel, not actively used during testing. Ferrite bead added close to the camera module (P/N: Würth Elektronik 742 721 1)

- CAN: CANbus Module inserted, but not actively used. CAN cable not connected

- WiFi and Bluetooth: Soldered directly on COM, placed in active scanning and discoverable mode, contributing to EMC spectrum. Depending on the temperature range, the default SPB228-D-3 or alternative CM-276NF module populated. Two antennas plugged and connected

- Console cable: Micro USB extension cable used only to setup the development kit, not plugged in during the measurements

- SD card: SD card (SanDisk) plugged in and used during read/write test

- Microphone: Microphone connected via 1.5m long cable, not actively used

- Headphones: Headphones connected via 2m long cable, not actively used

- Speakers: Line Out connected via 2m long cable, not actively used

Testing conditions and results

All the results were measured in compliance with the emission limits for FCC Class B (EMC standard EN 55032B). Class B devices are suitable for both residential and industrial applications as the norm standards use more restrictive limits.

iMX8M Industrial Development Kit Max - Module and peripherals under heavy load – PASSED

Test description:

- development kit configuration:

- iMX8M Industrial Module Max in Industrial temperature range

- iMX8M Development Baseboard in Extended temperature range

- CPU heavy testing threads using stressapptest

- DDR4 memory heavy testing threads using stressapptest

- Ethernet loopback cable used for network testing

- running heavy read/write testing for USB devices and SD card

- cables and devices plugged in but not actively used:

- peripherals heavy testing script used

Radiated Emissions

Both vertical and horizontal polarisation results in range from 30MHz to 1GHz were measured and captured during this EMC test session. Radiated emissions were measured and displayed as peak values. This relation is represented as a green curve in the measurements. The red highlighted line displays Class B limits. The Bilog antenna CBL6112A operating in range from 30MHz to 2GHz was used.

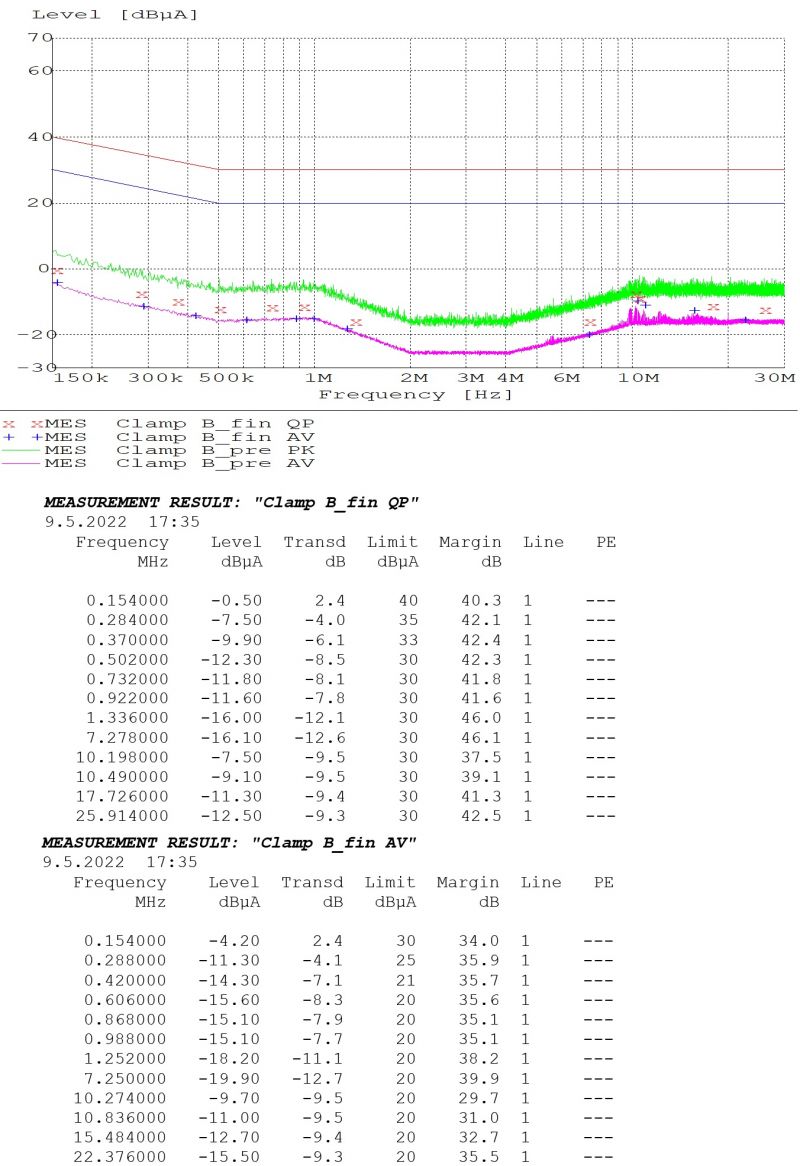

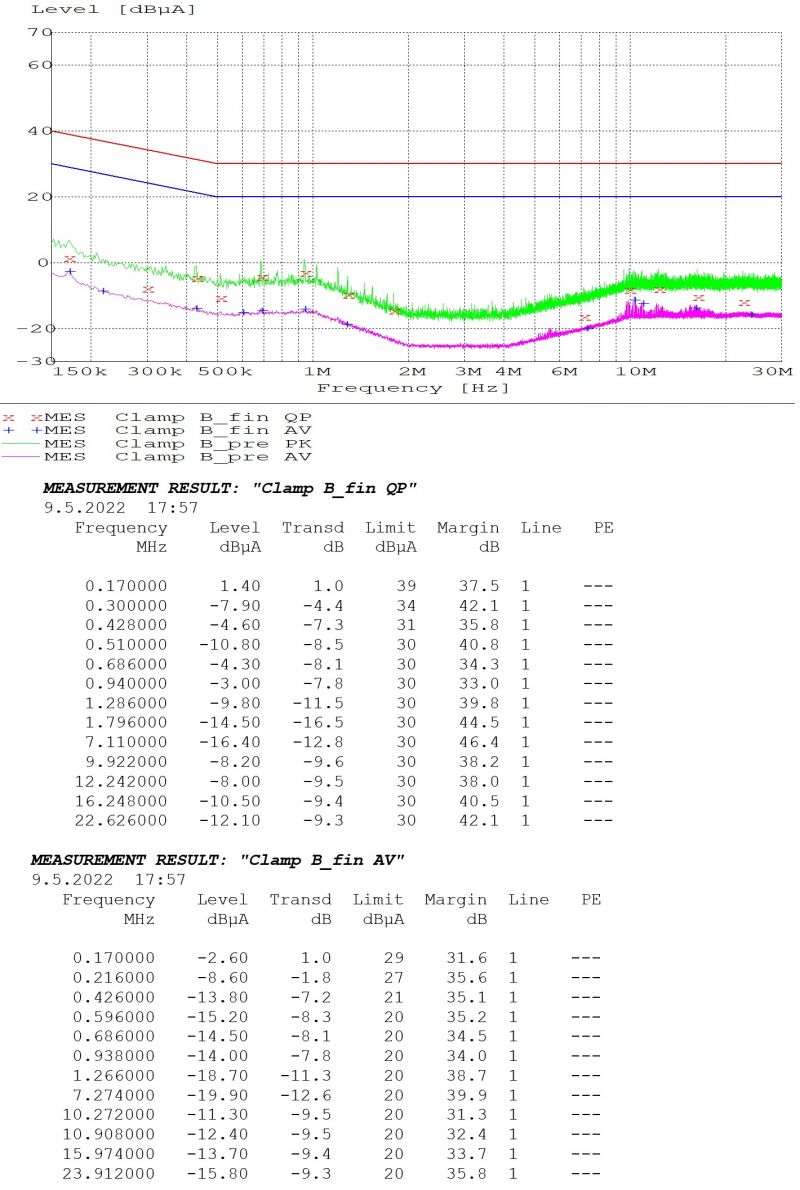

Conducted Emissions

iMX8M Industrial Development Kit Basic - Testing peripherals and external LCD display – PASSED

Test description:

- development kit configuration:

- iMX8M Industrial Module Basic in Industrial temperature range

- iMX8M Development Baseboard in Extended temperature range

- CPU heavy testing threads using stressapptest

- DDR4 memory heavy testing threads using stressapptest

- Ethernet loopback cable used for network testing

- running heavy read/write testing for USB devices and SD card

- LCD Newhaven LVDS Capacitive Display Set actively used

- cables and devices plugged in but not actively used:

- Digilent MIPI-CSI Camera Set

- two antennas with cables

- USB-C

- Audio jacks

- peripherals heavy testing script used

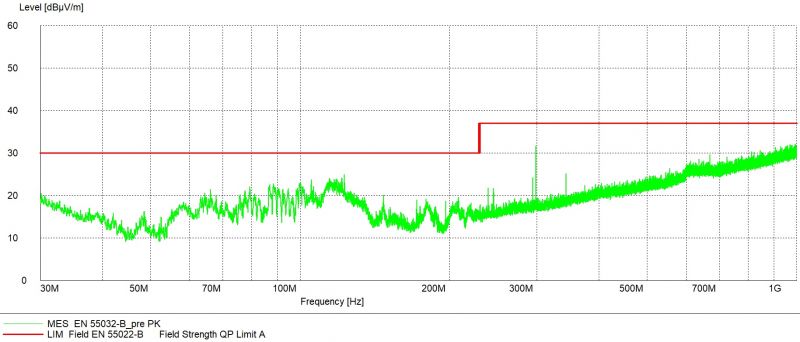

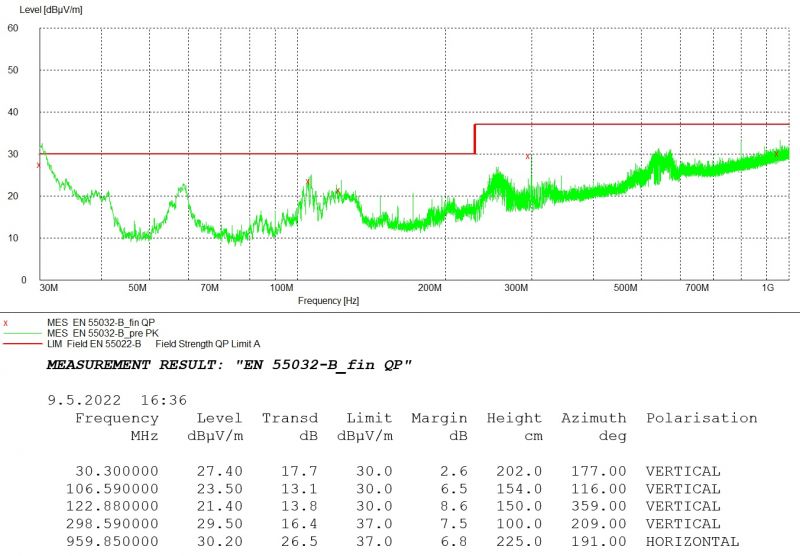

Radiated Emissions

The measurement starts with peak detection by scanning the whole frequency spectrum. This initial detection is plotted with the green curve at MES_EN_55032-B_pre_PK. Afterwards the five highest peaks were pointed and measured more thoroughly by quasi-peak method. These real measured values of the radiation are displayed with the red crosses at MES_EN_55032-B_fin_QP. The graph shows the setup passed the strict residential 55032-B limit represented by the red highlighted line.

The frequency spectrum around 30 MHz was heavily influenced by the power adapter used during this test. Further examination proved that input power sources emitting less noise lead to overall more superior results.

These results prove that iMX8M Industrial Development Kit, even under heavy load, meets the stricter limits even if no enclosure is used.

Vertical + Horizontal polarisation in lower band 30MHz - 1GHz

Antenna used: Bilog CBL6112A 30 MHz to 2GHz

Vertical + Horizontal polarisation in higher band 1GHz - 6GHz

Antenna used: Double-Ridged Waveguide Horn Antenna 1GHz to 18GHz

File:iMX8M Industrial Basic-Radiated emissions 1-6GHz.png

Conducted Emissions

iMX8M Industrial Development Kit Max - Testing module and DisplayPort output - PASSED

Test description:

- development kit configuration:

- iMX8M Industrial Module Max in Industrial temperature range

- iMX8M Development Baseboard in Extended temperature range

- CPU heavy testing threads using stressapptest

- DDR4 memory heavy testing threads using stressapptest

- Ethernet loopback cable used for network testing

- DisplayPort output tested in Full-HD 2560x1080 resolution

- cables and devices plugged in but not actively used:

- Digilent MIPI-CSI Camera Set

- two antennas with cables

- USB-C

- Audio jacks

- 2x USB 3.0

- module heavy testing script used

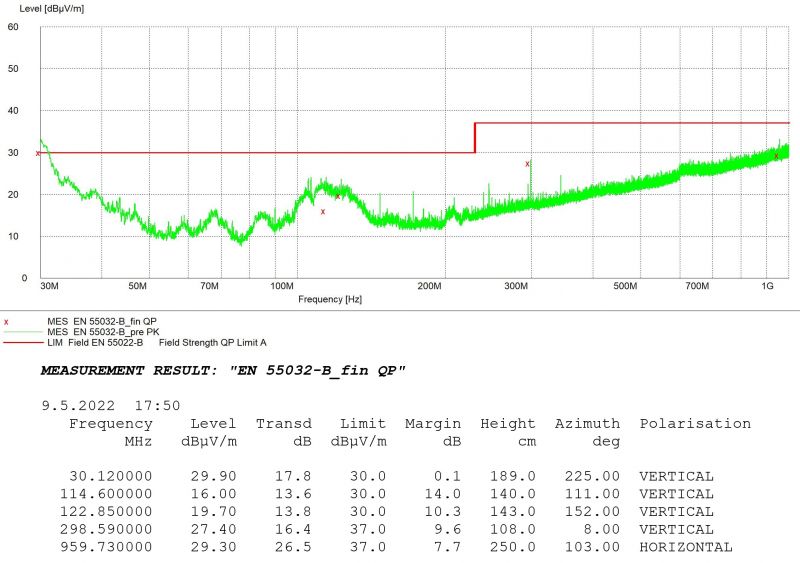

Radiated Emissions

The measurement starts with peak detection by scanning the whole frequency spectrum. This initial detection is plotted with the green curve at MES_EN_55032-B_pre_PK. Afterwards the five highest peaks were pointed and measured more thoroughly by quasi-peak method. These real measured values of the radiation are displayed with the red crosses at MES_EN_55032-B_fin_QP. The graph shows the setup passed the strict residential 55032-B limit represented by the red highlighted line.

The frequency spectrum around 30 MHz was heavily influenced by the power adapter used during this test. Further examination proved that input power sources emitting less noise lead to overall more superior results.

These results prove that iMX8M Industrial Development Kit, even under heavy load, meets the stricter limits even if no enclosure is used.

Vertical + Horizontal polarisation in lower band 30MHz - 1GHz

Antenna used: Bilog CBL6112A 30 MHz to 2GHz

Vertical + Horizontal polarisation in higher band 1GHz - 6GHz

Antenna used: Double-Ridged Waveguide Horn Antenna 1GHz to 18GHz

File:iMX8M Industrial Max-Radiated emissions 1-6GHz.png

Preparing the test

Boot device and software

These measurements were performed with boards using the actual hardware and software configuration of the web shop development kits.

eMMC Flash memory was selected as a booting device for all the measurements. U-Boot settings were not adjusted as the default configuration was used.

Running the script

Plug the development kit into mains and connect it to the controlling PC via console. Before the first time usage of the script, permissions need to be granted by the following command:

chmod +x imx8m-voipac-peripheral-test.sh

Testing scripts command consists of the following arguments:

- the first parameter - configuration of tested development kit (Max, Pro or Basic)

- the second parameter - USB drive 1 location

- the third parameter - USB drive 2 location

- the fourth parameter - SD card location

Several commands used during EMC testing are shown below:

- iMX8M Industrial Development Kit Max:

./imx8m-voipac-peripheral-test.sh -max sda1 sdb1 mmcblk1p1 | tee -i imx8m-emc-testing.log

- iMX8M Industrial Development Kit Pro:

./imx8m-voipac-peripheral-test.sh -pro sda1 sdb1 mmcblk1p1 | tee -i imx8m-emc-testing.log

- iMX8M Industrial Development Kit Basic:

./imx8m-voipac-peripheral-test.sh -basic sda1 sdb1 mmcblk1p1 | tee -i imx8m-emc-testing.log

Testing scripts

Peripherals heavy testing script

This code was used during the measurements, focusing on peripherals influence on the emissions. The complete script can also be found in the downloads section.

#!/bin/sh

# iMX8M Industrial Development Kit peripheral test

mountDevice() {

mkdir -p "/media/$2"

mount /dev/$1 /media/$2

cat /proc/mounts | grep -F "/dev/$1 /media/$2"

if [ "$?" -eq "0" ]; then

echo "$2 mounted"

else

echo "$2 not mounted"; exit 2

fi

}

# prepare files

cd ~/

mkdir -p imx8m-industrial-testing/

cd imx8m-industrial-testing/

touch imx8m-industrial-testing.log

touch cpu-temp.log

basic=0

pro=0

max=0

case $1 in

-basic) basic=1 ;;

-pro) pro=1 ;;

-max) max=1 ;;

*)

esac

# mount devices

mountDevice $2 usb0

mountDevice $3 usb1

mountDevice $4 mmc0

updateLogFiles() {

# obtain board ID from IP address - be sure addresses are allocated based on MAC

boardID=$(/sbin/ip -o -4 addr list eth0 | awk '{print $4}' | cut -d/ -f1 | cut -d'.' -f4 | cut -d'2' -f2);

# be sure time server is running on DHCP server

currentTime=`date +%Y-%m-%d.%H:%M`

mv imx8m-industrial-testing.log imx8m-industrial-$boardID-testing.log.$currentTime

mv cpu-temp.log imx8m-industrial-$boardID-cpu-temp.log.$currentTime

}

finish_test_now() {

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Ctrl+C Detected: End of the test"

precced=0;

#kill -INT $vid_pid $str_pid $log_pid;

sleep 3;

test_status=`cat imx8m-industrial-testing.log | grep -i "error" | grep -v -e "0 errors" -e "no corrected errors"`

if [ -z "$test_status" ]

then

echo "*********TEST PASS*********"

else

echo "*********TEST FAIL*********"

echo "List of detected errors:"

cat imx8m-industrial-testing.log | grep -i "error" | grep -v -e "0 errors" -e "no corrected errors" -e "List of detected errors:"

fi

updateLogFiles

exit;

}

# kill all processes if Ctrl+C is detected

trap finish_test_now 2

# play a video stream from HDMI input - testing also HDMI output

gst-launch-1.0 -q imxv4l2src ! autovideosink &

# stressapptest - one thread CPU, one thread memory, sata thread (if possible)

if [ "${basic}" -eq "1" ]; then

stress-ng --cpu 2 --vm 4 &

str_pid=$!

fi

if [ "${pro}" -eq "1" ]; then

stress-ng --cpu 4 --vm 4 &

str_pid=$!

fi

if [ "${max}" -eq "1" ]; then

stress-ng --cpu 4 --vm 4 &

str_pid=$!

fi

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Starting stressapptest with PID: " $str_pid

proceed=1

# create test files

file1_path=`mktemp`

file2_path=`mktemp`

file1=`basename $file1_path`

file2=`basename $file2_path`

dd if=/dev/urandom of=$file1_path bs=1024 count=10000

dd if=/dev/urandom of=$file2_path bs=1024 count=10000

cp1_from="/media/mmc0/"

cp1_to="/media/usb0/"

cp2_from="/media/usb0/"

cp2_to="/media/usb1/"

#copy files in case they are missing

cp $file1_path $cp1_from

cp $file1_path $cp1_to

cp $file2_path $cp2_from

cp $file2_path $cp2_to

while [ $proceed -eq 1 ]

do

# before running script check if the ip address exist

ping -q -c1 192.168.0.2 >> imx8m-industrial-testing.log

if [ $? -ne 0 ]

then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Ping failed"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Ping OK"

fi

cp1_done=`ps | grep $cp1_pid | grep cp`

if [ -z "$cp1_done" ]; then # copy finished

if cmp -s $cp1_from$file1 $cp1_to$file1; then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) PASS: Copying file from $cp1_from to $cp1_to successful"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Difference between files on $cp1_from and $cp1_to detected"

fi

cp1_temp=$cp1_from # swap destinations

cp1_from=$cp1_to

cp1_to=$cp1_temp

rm $cp1_to$file1 # remove destination file

cp $cp1_from$file1 $cp1_to$file1 &

cp1_pid=$!

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Started copying file from $cp1_from to $cp1_to"

fi

cp2_done=`ps | grep $cp2_pid | grep cp`

if [ -z "$cp2_done" ]; then # copy finished

if cmp -s $cp2_from$file2 $cp2_to$file2; then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) PASS: Copying file from $cp2_from to $cp2_to successful"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Difference between files on $cp2_from and $cp2_to detected"

fi

cp2_temp=$cp2_from # swap destinations

cp2_from=$cp2_to

cp2_to=$cp2_temp

rm $cp2_to$file2 # remove destination file

cp $cp2_from$file2 $cp2_to$file2 &

cp2_pid=$!

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Started copying file from $cp2_from to $cp2_to"

fi

done

Module heavy testing script

This script was utilised for testing procedure where the measurement was primarily focused on the module emissions. To use this script, plug the development kit into mains, connect it to controlling PC via console and copy the code below:

for d in $(seq 1 1 999) do uptime echo "Test $a Test $b Test $c $d times" echo "Start stress-ng --iomix 1 -t 10 -v" stress-ng --iomix 1 -t 10 -v echo "End" echo "Start Thermal zone information" stress-ng --matrix 0 --tz -t 10 --log-brief -t 10 echo "End" ping -q -c1 192.168.0.2 >> imx8m-industrial-testing.log if [ $? -ne 0 ] then echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Ping failed" fi echo "End" done