Difference between revisions of "iMX8M Industrial Environmental chamber testing"

| (134 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[Category:iMX8M Industrial Development Kit]] | [[Category:iMX8M Industrial Development Kit]] | ||

| + | [[Category:iMX8M Industrial Development Kit Testing]] | ||

<!-- --> | <!-- --> | ||

<div style="float:right">__TOC__</div> | <div style="float:right">__TOC__</div> | ||

| − | On this page environmental stress testing results of iMX8M Industrial Development Kit are displayed. Detailed instructions how to setup | + | On this page environmental stress testing results of iMX8M Industrial Development Kit are displayed. Detailed instructions how to setup kits are also shown. |

== Hardware configuration == | == Hardware configuration == | ||

| Line 9: | Line 10: | ||

<br /> | <br /> | ||

* 1x iMX8M Industrial Development Kit in [[iMX8M Industrial Max|Max configuration]] | * 1x iMX8M Industrial Development Kit in [[iMX8M Industrial Max|Max configuration]] | ||

| − | ** i.MX 8M Quad 1. | + | ** i.MX 8M Quad 1.3GHz CPU - extended industrial temperature range (-40°C to +105°C) |

| − | ** 4GB LPDDR4 Memory - extended industrial | + | ** 4GB LPDDR4 Memory - extended industrial temperature range (-40°C to +95°C) |

| − | ** eMMC 32GB - industrial | + | ** eMMC 32GB - industrial temperature range (-40°C to +85°C) |

| − | ** WiFi & Bluetooth - industrial | + | ** SPB228-D-3 WiFi & Bluetooth Module - industrial temperature range (-40°C to +85°C) |

<br /> | <br /> | ||

* 1x iMX8M Industrial Development Kit in [[iMX8M Industrial Pro|Pro configuration]] | * 1x iMX8M Industrial Development Kit in [[iMX8M Industrial Pro|Pro configuration]] | ||

| − | ** i.MX 8M | + | ** i.MX 8M QuadLite 1.3GHz CPU - extended industrial temperature range (-40°C to +105°C) |

| − | ** 2GB LPDDR4 Memory - automotive temperature range (-40°C to + | + | ** 2GB LPDDR4 Memory - automotive temperature range (-40°C to +95°C) |

| − | ** eMMC 16GB - industrial | + | ** eMMC 16GB - industrial temperature range (-40°C to +85°C) |

| − | ** WiFi & Bluetooth - industrial | + | ** SPB228-D-3 WiFi & Bluetooth Module - industrial temperature range (-40°C to +85°C) |

<br /> | <br /> | ||

| − | * 1x iMX8M Industrial Development Kit in [[iMX8M Industrial | + | * 1x iMX8M Industrial Development Kit in [[iMX8M Industrial Basic|Basic configuration]] |

| − | ** i.MX 8M | + | ** i.MX 8M Dual 1.3GHz CPU - extended industrial temperature range (-40°C to +105°C) |

| − | ** | + | ** 1GB LPDDR4 Memory - industrial temperature range (-40°C to +95°C) |

| − | ** eMMC | + | ** eMMC 8GB - industrial temperature range (-40°C to +85°C) |

| − | |||

<br /> | <br /> | ||

| − | * 1x iMX8M Industrial Development Kit in [[iMX8M Industrial | + | * 1x iMX8M Industrial Development Kit in [[iMX8M Industrial Max|Max configuration]] |

| − | ** i.MX 8M Quad 1.5GHz CPU - extended | + | ** i.MX 8M Quad 1.5GHz CPU - extended commercial temperature range (0°C to +95°C) |

| − | ** | + | ** 4GB LPDDR4 Memory - industrial temperature range (-30°C to +85°C) |

| − | ** eMMC | + | ** eMMC 32GB - extended temperature range (-25°C to +85°C) |

| − | ** WiFi & Bluetooth - industrial | + | ** CM-276NF WiFi & Bluetooth Module - industrial temperature range (-30°C to +85°C) |

<br /> | <br /> | ||

| − | All of the tested modules used standard configuration of | + | All of the tested modules used standard configuration of iMX Development Baseboard with extended temperature range (-20°C to +70°C). The majority of tested kits used the standard heatsink sized 25x25x25mm, which is included in every development kit package, thus showcasing that this standardised heatsink performs even in very harsh conditions. One of the kits was mounted with a larger heatsink and one of the standard heatsinks was mounted with an active fan to test its impact on the performance.<br /> |

| + | To test the performance of the video capturing capabilities of the development kits under extreme conditions, NXP MIPI-CSI and Digilent MIPI-CSI cameras were included in the tested setups. | ||

<br /> | <br /> | ||

The setup in the environmental chamber:<br /> | The setup in the environmental chamber:<br /> | ||

| − | [[image: | + | [[image:iMX8M_Industrial_Development_Kits-Enviromental_chamber_overview_with_description.jpg|800px]] |

== Test description == | == Test description == | ||

| − | Four iMX8M Industrial Development Kits (one in Max configuration, one in Pro configuration, one in | + | Four iMX8M Industrial Development Kits (one in Max Industrial configuration, one in Pro Industrial configuration, one in Basic Industrial configuration and one in Max Commercial configuration) were running CPU and memory tests to stress out all the most significant peripherals in the whole Industrial temperature scale, ranging from -40°C to +85°C, to check the reliability and stability of the firmware and hardware design.<br /><br /> |

Configuration, software and testing threads in details:<br /><br /> | Configuration, software and testing threads in details:<br /><br /> | ||

| − | '''1x iMX8M Industrial Development Kit [ | + | '''1x iMX8M Industrial Development Kit [setup no. 4] in [[iMX8M Industrial Max|Max configuration]] and Industrial temperature range<br />CPU and memory stress testing''' |

| − | * 1 thread of extensive Memory stress test | + | * 1 thread of extensive DDR4 Memory stress test |

* 1 thread of CPU stress test | * 1 thread of CPU stress test | ||

* sending HDMI Output to external monitor | * sending HDMI Output to external monitor | ||

| − | + | * all the messages were displayed on the serial console connected via Micro USB cable | |

| − | + | * firmware running from eMMC Flash memory | |

| − | + | * Ethernet cable connected to network switch placed outside of the chamber | |

| − | * all the messages were | + | * 2x USB device connected and placed outside of the chamber |

| − | * firmware running from eMMC | + | * WiFi and Bluetooth module active, connected to the antennas and running discovery mode |

| − | * | + | * large 48x48x16mm heatsink |

<br /> | <br /> | ||

| − | '''1x iMX8M Industrial Development Kit [ | + | '''1x iMX8M Industrial Development Kit [setup no. 2] in [[iMX8M Industrial Pro|Pro configuration]] and Industrial temperature range<br />CPU and memory stress testing''' |

| − | * 1 thread of extensive Memory stress test | + | * 1 thread of extensive DDR4 Memory stress test |

* 1 thread of CPU stress test | * 1 thread of CPU stress test | ||

* sending HDMI Output to external monitor | * sending HDMI Output to external monitor | ||

| − | * | + | * NXP MIPI-CSI camera connected and capturing video stream |

| − | + | * all the messages were displayed on the serial console connected via Micro USB cable | |

| − | + | * firmware running from eMMC Flash memory | |

| − | * all the messages were | + | * Ethernet cable connected to network switch placed outside of the chamber |

| − | * firmware running from eMMC | + | * 2x USB device connected and placed outside of the chamber |

| − | * | + | * WiFi and Bluetooth module active, connected to the antennas and running discovery mode |

| + | * standard 25x25x25mm heatsink | ||

<br /> | <br /> | ||

| − | '''1x iMX8M Industrial Development Kit [ | + | '''1x iMX8M Industrial Development Kit [setup no. 1] in [[iMX8M Industrial Basic|Basic configuration]] and Industrial temperature range<br />CPU and memory stress testing''' |

| − | * 1 thread of extensive Memory stress test | + | * 1 thread of extensive DDR4 Memory stress test |

* 1 thread of CPU stress test | * 1 thread of CPU stress test | ||

* sending HDMI Output to external monitor | * sending HDMI Output to external monitor | ||

| − | + | * all the messages were displayed on the serial console connected via Micro USB cable | |

| − | + | * firmware running from eMMC Flash memory | |

| − | + | * Ethernet cable connected to network switch placed outside of the chamber | |

| − | * all the messages were | + | * 2x USB device connected and placed outside of the chamber |

| − | * firmware running from eMMC | + | * WiFi PCI Express card plugged in, connected to the antennas and running discovery mode |

* standard 25x25x25mm heatsink | * standard 25x25x25mm heatsink | ||

<br /> | <br /> | ||

| − | '''1x iMX8M Industrial Development Kit [ | + | '''1x iMX8M Industrial Development Kit [setup no. 3] in [[iMX8M Industrial Max|Max configuration]] and Commercial temperature range<br />CPU and memory stress testing''' |

| − | * 1 thread of extensive Memory stress test | + | * 1 thread of extensive DDR4 Memory stress test |

* 1 thread of CPU stress test | * 1 thread of CPU stress test | ||

* sending HDMI Output to external monitor | * sending HDMI Output to external monitor | ||

| − | * | + | * Digilent MIPI-CSI camera connected and capturing video stream |

| − | + | * all the messages were displayed on the serial console connected via Micro USB cable | |

| − | + | * firmware running from eMMC Flash memory | |

| − | * all the messages were | + | * Ethernet cable connected to network switch placed outside of the chamber |

| − | * firmware running from eMMC | + | * 2x USB device connected and placed outside of the chamber |

| − | * standard 25x25x25mm heatsink | + | * WiFi and Bluetooth module active, connected to the antennas and running discovery mode |

| + | * standard 25x25x25mm heatsink including a fan | ||

<br /> | <br /> | ||

| − | USB flash devices were placed outside the environmental chamber. All the scripts running during the test and the board setup instructions can be found in section [[#Preparing the test|How to prepare the test]]. | + | Power sources, USB flash devices, network switch, HDMI monitor and controlling PC were placed outside the environmental chamber. All the scripts running during the test and the board setup instructions can be found in section [[#Preparing the test|How to prepare the test]]. |

== Testing Results == | == Testing Results == | ||

| − | The picture below shows the temperature profile during the whole testing process | + | The picture below shows the temperature profile during the whole testing process. Humidity was not controlled. The temperature gradient for the environment chamber was set to 1°C/min.<br /> |

| − | [[image: | + | [[image:iMX8M_Industrial_Development_Kit-Env_chamber_temperature_profile.png|800px]] |

| − | === Running the | + | === Running the development kits at -40°C – PASS === |

| − | Test description: CPU, Memory and peripheral stress tests were running at -40°C. All the tested kits were working without errors during the whole time, even if some components used for iMX8M | + | Test description: CPU, Memory and peripheral stress tests were running at -40°C. All the tested kits were working without errors during the whole time, even if some components used for iMX8M Industrial Development Kit Max in Commercial temperature range were only rated for the temperature range between 0°C and +95°C.<br /><br /> |

A closer image on the temperature chamber displaying the minimum temperature is shown below. These readouts are available on the display: | A closer image on the temperature chamber displaying the minimum temperature is shown below. These readouts are available on the display: | ||

* the first number shows current temperature | * the first number shows current temperature | ||

* the second one set temperature | * the second one set temperature | ||

| − | * the last two shows | + | * the last two shows relative humidity. Humidity was not controlled during testing process. |

| − | [[image:iMX8M Industrial Kit-Env chamber-Boards at | + | [[image:iMX8M Industrial Kit-Env chamber-Boards at -40C.jpg|800px]] |

| + | <br /><br /> | ||

| + | [[image:iMX8M_Industrial_Development_Kit-Env_chamber_at_-40C.jpg|800px]] | ||

| − | === Running the kits at | + | === Running the development kits at +85°C – PASS === |

| − | Test description: The | + | Test description: The pre-set temperature profile was followed until the development kits gradually reached +85°C. The kits remained around this temperature for the duration of two hours and at the end of this whole cycle all the kits were running.<br /> |

| − | |||

| − | + | When using both the iMX8M and iMX93 Industrial Modules with common baseboard, please note the difference when the CPUs are above the critically high temperature of +85°C:<br /> | |

| − | + | '''''i.MX 8M CPU – waiting for the temperature decline, than reboots itself'''''<br /> | |

| + | '''''i.MX 93 CPU – powers down''''' | ||

| − | + | [[image:iMX8M_Industrial_Kit-Env_chamber-Boards_at_+86C.jpg|800px]] | |

| − | + | <br /><br /> | |

| − | + | [[image:iMX8M_Industrial_Development_Kit-Env_chamber_at_+85C.jpg|800px]] | |

| − | |||

| − | |||

| − | |||

| − | == | + | === Switch OFF/ON test at -40°C – PASS === |

| − | + | Test description: At temperature -40°C the development kits were switched OFF, left OFF for at least 15 minutes (to cool down completely) and then switched ON to see if they boot up without problems. Once booted up into Linux, the test script was launched to test RAM memory and all peripherals. The kits were turned OFF and ON again multiple times to see potential issues at the lowest temperature level. All of the tested setups booted up successfully. | |

| − | + | <br /> | |

| − | + | [[image:iMX8M Industrial Kit-Env chamber-Boards snow.jpg|800px]] | |

| − | [[image: | ||

| − | == | + | == PC setup == |

| − | + | The PC was used during the test to control / monitor all the kits through serial console sessions. The control computer was running Windows 10 operating system. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | === | + | === HDMI Outputs and Serial consoles === |

| − | To control | + | To control iMX8M Industrial Development Kits, one TeraTerm serial console was opened for each setup. The kits were connected to the external HDMI switch to monitor HDMI outputs. |

| − | |||

<br /><br /> | <br /><br /> | ||

| − | The setup of the environmental chamber cables and out-of-chamber equipment:<br /> | + | The setup of the environmental chamber cables and out-of-chamber equipment: |

| − | [[image: | + | <br /> |

| + | [[image:iMX8M Industrial Development Kit-Climate chamber overview.jpg|800px]] | ||

== Preparing the test == | == Preparing the test == | ||

=== Boot device and software === | === Boot device and software === | ||

| − | + | The eMMC memory was selected as a booting device for all the kits. Device tree files were not adjusted as the default configuration was used. The only change compared to standard software package was running the test script. In order to flash a fresh firmware into the eMMC Memory follow [[iMX8M_Industrial_Flashing_Procedure|these instructions]]. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=== Downloading stress test === | === Downloading stress test === | ||

| − | + | Stress-ng package was selected to check CPU and memory integrity. Placing this file into the same directory where the testing script will be stored is important: | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

| − | + | wget https://downloads.voipac.com/files/iMX8M_Industrial_Development_Kit/module/documents/Thermal_stress_resistance/imx8mq-voipac-peripheral-test.sh | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</syntaxhighlight> | </syntaxhighlight> | ||

=== Start CPU and memory stress test === | === Start CPU and memory stress test === | ||

| − | Navigate into the directory, where | + | Navigate into the directory, where stress test feature and the testing script are stored.<br /><br /> |

| − | Stress | + | Stress sequence script: |

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

| − | + | for d in $(seq 1 1 99999) | |

| − | + | do | |

| − | + | uptime | |

| − | + | echo "Test $a Test $b Test $c $d times" | |

| − | + | echo "Start stress-ng --iomix 1 -t 10 -v" | |

| − | + | stress-ng --iomix 1 -t 10 -v | |

| − | + | echo "End" | |

| − | + | echo "Start stress-ng --cpu 2 --vm 4 -t 10" | |

| − | + | stress-ng --cpu 2 --vm 4 -t 10 | |

| − | + | echo "End" | |

| − | + | echo "Start stress-ng --shm 0 -t 10" | |

| + | stress-ng --shm 0 -t 10 | ||

| + | echo "End" | ||

| + | echo "Start stress-ng --seq 0 -t 2 --tz -v" | ||

| + | stress-ng --seq 0 -t 2 --tz -v | ||

| + | echo "End" | ||

| + | echo "Start Thermal zone information" | ||

| + | stress-ng --matrix 0 --tz -t 10 --log-brief -t 10 | ||

| + | echo "End" | ||

| + | done | ||

</syntaxhighlight> | </syntaxhighlight> | ||

=== Start peripheral test === | === Start peripheral test === | ||

| − | + | Plug the development kit into mains and connect it to the controlling PC via console. Before the first time usage of the script, permissions need to be granted by the following command: | |

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

| − | + | chmod +x imx8m-voipac-peripheral-test.sh | |

</syntaxhighlight> | </syntaxhighlight> | ||

| + | <br /> | ||

| + | Testing scripts command consists of the following arguments: | ||

| + | * the first parameter - configuration of tested development kit (Max, Pro or Basic) | ||

| + | * the second parameter - USB drive 1 location | ||

| + | * the third parameter - USB drive 2 location | ||

| + | * the fourth parameter - SD card location | ||

| + | <br /> | ||

| + | Several commands used during environmental chamber testing are shown below: | ||

| − | + | * iMX8M Industrial Development Kit Max: | |

| − | |||

| − | |||

| − | |||

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

| − | ./ | + | ./imx8m-voipac-peripheral-test.sh -max sda1 sdb1 mmcblk1p1 | tee -i imx8m-env-testing.log |

</syntaxhighlight> | </syntaxhighlight> | ||

| − | + | * iMX8M Industrial Development Kit Pro: | |

| − | |||

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

| − | ./ | + | ./imx8m-voipac-peripheral-test.sh -pro sda1 sdb1 mmcblk1p1 | tee -i imx8m-env-testing.log |

</syntaxhighlight> | </syntaxhighlight> | ||

| − | + | * iMX8M Industrial Development Kit Basic: | |

| − | |||

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

| − | ./ | + | ./imx8m-voipac-peripheral-test.sh -basic sda1 sdb1 mmcblk1p1 | tee -i imx8m-env-testing.log |

</syntaxhighlight> | </syntaxhighlight> | ||

| − | + | <br /> | |

| − | The complete script can be found in [ | + | The complete script can be found in [https://downloads.voipac.com/files/iMX8M_Industrial_Development_Kit/module/documents/Thermal_stress_resistance/imx8mq-voipac-peripheral-test.sh the downloads section] or down below: |

<syntaxhighlight lang="bash"> | <syntaxhighlight lang="bash"> | ||

#!/bin/sh | #!/bin/sh | ||

| Line 313: | Line 269: | ||

trap finish_test_now 2 | trap finish_test_now 2 | ||

| − | # play a video stream | + | # play a video stream |

gst-launch-1.0 -q imxv4l2src ! autovideosink & | gst-launch-1.0 -q imxv4l2src ! autovideosink & | ||

| − | # stressapptest - | + | # stressapptest - CPU threads and RAM memory threads |

if [ "${basic}" -eq "1" ]; then | if [ "${basic}" -eq "1" ]; then | ||

stress-ng --cpu 2 --vm 4 & | stress-ng --cpu 2 --vm 4 & | ||

| Line 356: | Line 312: | ||

do | do | ||

| − | ping -q -c1 | + | ping -q -c1 192.168.0.2 >> env-chamber-testing.log |

if [ $? -ne 0 ] | if [ $? -ne 0 ] | ||

then | then | ||

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Ping failed" | echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Ping failed" | ||

| − | |||

| − | |||

fi | fi | ||

| Line 401: | Line 355: | ||

done | done | ||

| + | </syntaxhighlight> | ||

| + | === Starting camera capture === | ||

| + | ==== Digilent camera ==== | ||

| + | To initiate the camera to start the capturing of video stream, following command can be used: | ||

| + | <syntaxhighlight lang="bash"> | ||

| + | GST_DEBUG=GST_BUFFER:5 gst-launch-1.0 v4l2src device=/dev/video1 ! 'video/x-raw,framerate=30/1' ! autovideosink | ||

</syntaxhighlight> | </syntaxhighlight> | ||

| − | < | + | ==== NXP camera ==== |

| + | To initiate the camera to start the capturing of video stream, following command can be used: | ||

| + | <syntaxhighlight lang="bash"> | ||

| + | GST_DEBUG=GST_BUFFER:5 gst-launch-1.0 v4l2src device=/dev/video0 ! 'video/x-raw,framerate=30/1' ! autovideosink | ||

| + | </syntaxhighlight> | ||

Latest revision as of 17:14, 14 May 2025

On this page environmental stress testing results of iMX8M Industrial Development Kit are displayed. Detailed instructions how to setup kits are also shown.

Hardware configuration

All of the modules used standard specification except of the temperature ranges for the key components as described below:

- 1x iMX8M Industrial Development Kit in Max configuration

- i.MX 8M Quad 1.3GHz CPU - extended industrial temperature range (-40°C to +105°C)

- 4GB LPDDR4 Memory - extended industrial temperature range (-40°C to +95°C)

- eMMC 32GB - industrial temperature range (-40°C to +85°C)

- SPB228-D-3 WiFi & Bluetooth Module - industrial temperature range (-40°C to +85°C)

- 1x iMX8M Industrial Development Kit in Pro configuration

- i.MX 8M QuadLite 1.3GHz CPU - extended industrial temperature range (-40°C to +105°C)

- 2GB LPDDR4 Memory - automotive temperature range (-40°C to +95°C)

- eMMC 16GB - industrial temperature range (-40°C to +85°C)

- SPB228-D-3 WiFi & Bluetooth Module - industrial temperature range (-40°C to +85°C)

- 1x iMX8M Industrial Development Kit in Basic configuration

- i.MX 8M Dual 1.3GHz CPU - extended industrial temperature range (-40°C to +105°C)

- 1GB LPDDR4 Memory - industrial temperature range (-40°C to +95°C)

- eMMC 8GB - industrial temperature range (-40°C to +85°C)

- 1x iMX8M Industrial Development Kit in Max configuration

- i.MX 8M Quad 1.5GHz CPU - extended commercial temperature range (0°C to +95°C)

- 4GB LPDDR4 Memory - industrial temperature range (-30°C to +85°C)

- eMMC 32GB - extended temperature range (-25°C to +85°C)

- CM-276NF WiFi & Bluetooth Module - industrial temperature range (-30°C to +85°C)

All of the tested modules used standard configuration of iMX Development Baseboard with extended temperature range (-20°C to +70°C). The majority of tested kits used the standard heatsink sized 25x25x25mm, which is included in every development kit package, thus showcasing that this standardised heatsink performs even in very harsh conditions. One of the kits was mounted with a larger heatsink and one of the standard heatsinks was mounted with an active fan to test its impact on the performance.

To test the performance of the video capturing capabilities of the development kits under extreme conditions, NXP MIPI-CSI and Digilent MIPI-CSI cameras were included in the tested setups.

The setup in the environmental chamber:

Test description

Four iMX8M Industrial Development Kits (one in Max Industrial configuration, one in Pro Industrial configuration, one in Basic Industrial configuration and one in Max Commercial configuration) were running CPU and memory tests to stress out all the most significant peripherals in the whole Industrial temperature scale, ranging from -40°C to +85°C, to check the reliability and stability of the firmware and hardware design.

Configuration, software and testing threads in details:

1x iMX8M Industrial Development Kit [setup no. 4] in Max configuration and Industrial temperature range

CPU and memory stress testing

- 1 thread of extensive DDR4 Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- all the messages were displayed on the serial console connected via Micro USB cable

- firmware running from eMMC Flash memory

- Ethernet cable connected to network switch placed outside of the chamber

- 2x USB device connected and placed outside of the chamber

- WiFi and Bluetooth module active, connected to the antennas and running discovery mode

- large 48x48x16mm heatsink

1x iMX8M Industrial Development Kit [setup no. 2] in Pro configuration and Industrial temperature range

CPU and memory stress testing

- 1 thread of extensive DDR4 Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- NXP MIPI-CSI camera connected and capturing video stream

- all the messages were displayed on the serial console connected via Micro USB cable

- firmware running from eMMC Flash memory

- Ethernet cable connected to network switch placed outside of the chamber

- 2x USB device connected and placed outside of the chamber

- WiFi and Bluetooth module active, connected to the antennas and running discovery mode

- standard 25x25x25mm heatsink

1x iMX8M Industrial Development Kit [setup no. 1] in Basic configuration and Industrial temperature range

CPU and memory stress testing

- 1 thread of extensive DDR4 Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- all the messages were displayed on the serial console connected via Micro USB cable

- firmware running from eMMC Flash memory

- Ethernet cable connected to network switch placed outside of the chamber

- 2x USB device connected and placed outside of the chamber

- WiFi PCI Express card plugged in, connected to the antennas and running discovery mode

- standard 25x25x25mm heatsink

1x iMX8M Industrial Development Kit [setup no. 3] in Max configuration and Commercial temperature range

CPU and memory stress testing

- 1 thread of extensive DDR4 Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- Digilent MIPI-CSI camera connected and capturing video stream

- all the messages were displayed on the serial console connected via Micro USB cable

- firmware running from eMMC Flash memory

- Ethernet cable connected to network switch placed outside of the chamber

- 2x USB device connected and placed outside of the chamber

- WiFi and Bluetooth module active, connected to the antennas and running discovery mode

- standard 25x25x25mm heatsink including a fan

Power sources, USB flash devices, network switch, HDMI monitor and controlling PC were placed outside the environmental chamber. All the scripts running during the test and the board setup instructions can be found in section How to prepare the test.

Testing Results

The picture below shows the temperature profile during the whole testing process. Humidity was not controlled. The temperature gradient for the environment chamber was set to 1°C/min.

Running the development kits at -40°C – PASS

Test description: CPU, Memory and peripheral stress tests were running at -40°C. All the tested kits were working without errors during the whole time, even if some components used for iMX8M Industrial Development Kit Max in Commercial temperature range were only rated for the temperature range between 0°C and +95°C.

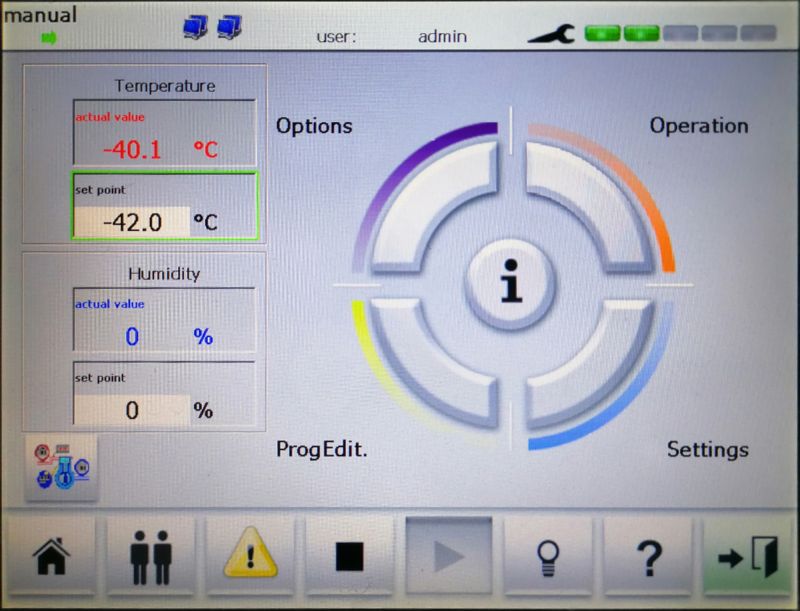

A closer image on the temperature chamber displaying the minimum temperature is shown below. These readouts are available on the display:

- the first number shows current temperature

- the second one set temperature

- the last two shows relative humidity. Humidity was not controlled during testing process.

Running the development kits at +85°C – PASS

Test description: The pre-set temperature profile was followed until the development kits gradually reached +85°C. The kits remained around this temperature for the duration of two hours and at the end of this whole cycle all the kits were running.

When using both the iMX8M and iMX93 Industrial Modules with common baseboard, please note the difference when the CPUs are above the critically high temperature of +85°C:

i.MX 8M CPU – waiting for the temperature decline, than reboots itself

i.MX 93 CPU – powers down

Switch OFF/ON test at -40°C – PASS

Test description: At temperature -40°C the development kits were switched OFF, left OFF for at least 15 minutes (to cool down completely) and then switched ON to see if they boot up without problems. Once booted up into Linux, the test script was launched to test RAM memory and all peripherals. The kits were turned OFF and ON again multiple times to see potential issues at the lowest temperature level. All of the tested setups booted up successfully.

PC setup

The PC was used during the test to control / monitor all the kits through serial console sessions. The control computer was running Windows 10 operating system.

HDMI Outputs and Serial consoles

To control iMX8M Industrial Development Kits, one TeraTerm serial console was opened for each setup. The kits were connected to the external HDMI switch to monitor HDMI outputs.

The setup of the environmental chamber cables and out-of-chamber equipment:

Preparing the test

Boot device and software

The eMMC memory was selected as a booting device for all the kits. Device tree files were not adjusted as the default configuration was used. The only change compared to standard software package was running the test script. In order to flash a fresh firmware into the eMMC Memory follow these instructions.

Downloading stress test

Stress-ng package was selected to check CPU and memory integrity. Placing this file into the same directory where the testing script will be stored is important:

wget https://downloads.voipac.com/files/iMX8M_Industrial_Development_Kit/module/documents/Thermal_stress_resistance/imx8mq-voipac-peripheral-test.sh

Start CPU and memory stress test

Navigate into the directory, where stress test feature and the testing script are stored.

Stress sequence script:

for d in $(seq 1 1 99999) do uptime echo "Test $a Test $b Test $c $d times" echo "Start stress-ng --iomix 1 -t 10 -v" stress-ng --iomix 1 -t 10 -v echo "End" echo "Start stress-ng --cpu 2 --vm 4 -t 10" stress-ng --cpu 2 --vm 4 -t 10 echo "End" echo "Start stress-ng --shm 0 -t 10" stress-ng --shm 0 -t 10 echo "End" echo "Start stress-ng --seq 0 -t 2 --tz -v" stress-ng --seq 0 -t 2 --tz -v echo "End" echo "Start Thermal zone information" stress-ng --matrix 0 --tz -t 10 --log-brief -t 10 echo "End" done

Start peripheral test

Plug the development kit into mains and connect it to the controlling PC via console. Before the first time usage of the script, permissions need to be granted by the following command:

chmod +x imx8m-voipac-peripheral-test.sh

Testing scripts command consists of the following arguments:

- the first parameter - configuration of tested development kit (Max, Pro or Basic)

- the second parameter - USB drive 1 location

- the third parameter - USB drive 2 location

- the fourth parameter - SD card location

Several commands used during environmental chamber testing are shown below:

- iMX8M Industrial Development Kit Max:

./imx8m-voipac-peripheral-test.sh -max sda1 sdb1 mmcblk1p1 | tee -i imx8m-env-testing.log

- iMX8M Industrial Development Kit Pro:

./imx8m-voipac-peripheral-test.sh -pro sda1 sdb1 mmcblk1p1 | tee -i imx8m-env-testing.log

- iMX8M Industrial Development Kit Basic:

./imx8m-voipac-peripheral-test.sh -basic sda1 sdb1 mmcblk1p1 | tee -i imx8m-env-testing.log

The complete script can be found in the downloads section or down below:

#!/bin/sh

# iMX8MQ environmental chamber peripheral test

mountDevice() {

mkdir -p "/media/$2"

mount /dev/$1 /media/$2

cat /proc/mounts | grep -F "/dev/$1 /media/$2"

if [ "$?" -eq "0" ]; then

echo "$2 mounted"

else

echo "$2 not mounted"; exit 2

fi

}

# prepare files

cd ~/

mkdir -p env-chamber-testing/

cd env-chamber-testing/

touch env-chamber-testing.log

touch cpu-temp.log

basic=0

pro=0

max=0

case $1 in

-basic) basic=1 ;;

-pro) pro=1 ;;

-max) max=1 ;;

*)

esac

# mount devices

mountDevice $2 usb0

mountDevice $3 usb1

mountDevice $4 mmc0

updateLogFiles() {

# obtain board ID from IP address - be sure addresses are allocated based on MAC

boardID=$(/sbin/ip -o -4 addr list eth0 | awk '{print $4}' | cut -d/ -f1 | cut -d'.' -f4 | cut -d'2' -f2);

# be sure time server is running on DHCP server

currentTime=`date +%Y-%m-%d.%H:%M`

mv env-chamber-testing.log trx-board-$boardID-env-chamber.log.$currentTime

mv cpu-temp.log trx-board-$boardID-env-cpu-temp.log.$currentTime

}

finish_test_now() {

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Ctrl+C Detected: End of the test"

precced=0;

#kill -INT $vid_pid $str_pid $log_pid;

sleep 3;

test_status=`cat env-chamber-testing.log | grep -i "error" | grep -v -e "0 errors" -e "no corrected errors"`

if [ -z "$test_status" ]

then

echo "*********TEST PASS*********"

else

echo "*********TEST FAIL*********"

echo "List of detected errors:"

cat env-chamber-testing.log | grep -i "error" | grep -v -e "0 errors" -e "no corrected errors" -e "List of detected errors:"

fi

updateLogFiles

exit;

}

# kill all processes if Ctrl+C is detected

trap finish_test_now 2

# play a video stream

gst-launch-1.0 -q imxv4l2src ! autovideosink &

# stressapptest - CPU threads and RAM memory threads

if [ "${basic}" -eq "1" ]; then

stress-ng --cpu 2 --vm 4 &

str_pid=$!

fi

if [ "${pro}" -eq "1" ]; then

stress-ng --cpu 4 --vm 4 &

str_pid=$!

fi

if [ "${max}" -eq "1" ]; then

stress-ng --cpu 4 --vm 4 &

str_pid=$!

fi

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Starting stressapptest with PID: " $str_pid

proceed=1

# create test files

file1_path=`mktemp`

file2_path=`mktemp`

file1=`basename $file1_path`

file2=`basename $file2_path`

dd if=/dev/urandom of=$file1_path bs=1024 count=10000

dd if=/dev/urandom of=$file2_path bs=1024 count=10000

cp1_from="/media/mmc0/"

cp1_to="/media/usb0/"

cp2_from="/media/usb0/"

cp2_to="/media/usb1/"

#copy files in case they are missing

cp $file1_path $cp1_from

cp $file1_path $cp1_to

cp $file2_path $cp2_from

cp $file2_path $cp2_to

while [ $proceed -eq 1 ]

do

ping -q -c1 192.168.0.2 >> env-chamber-testing.log

if [ $? -ne 0 ]

then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Ping failed"

fi

cp1_done=`ps | grep $cp1_pid | grep cp`

if [ -z "$cp1_done" ]; then # copy finished

if cmp -s $cp1_from$file1 $cp1_to$file1; then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) PASS: Copying file from $cp1_from to $cp1_to successful"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Difference between files on $cp1_from and $cp1_to detected"

fi

cp1_temp=$cp1_from # swap destinations

cp1_from=$cp1_to

cp1_to=$cp1_temp

rm $cp1_to$file1 # remove destination file

cp $cp1_from$file1 $cp1_to$file1 &

cp1_pid=$!

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Started copying file from $cp1_from to $cp1_to"

fi

cp2_done=`ps | grep $cp2_pid | grep cp`

if [ -z "$cp2_done" ]; then # copy finished

if cmp -s $cp2_from$file2 $cp2_to$file2; then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) PASS: Copying file from $cp2_from to $cp2_to successful"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Difference between files on $cp2_from and $cp2_to detected"

fi

cp2_temp=$cp2_from # swap destinations

cp2_from=$cp2_to

cp2_to=$cp2_temp

rm $cp2_to$file2 # remove destination file

cp $cp2_from$file2 $cp2_to$file2 &

cp2_pid=$!

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Started copying file from $cp2_from to $cp2_to"

fi

done

Starting camera capture

Digilent camera

To initiate the camera to start the capturing of video stream, following command can be used:

GST_DEBUG=GST_BUFFER:5 gst-launch-1.0 v4l2src device=/dev/video1 ! 'video/x-raw,framerate=30/1' ! autovideosink

NXP camera

To initiate the camera to start the capturing of video stream, following command can be used:

GST_DEBUG=GST_BUFFER:5 gst-launch-1.0 v4l2src device=/dev/video0 ! 'video/x-raw,framerate=30/1' ! autovideosink