Difference between revisions of "iMX8M Industrial Environmental chamber testing"

| Line 105: | Line 105: | ||

Test description: The ambient temperature was gradually increasing (from 60°C up to 100°C) while CPU, Memory and peripheral stress tests were running. The moment when CPU frequency had decreased was used as a test threshold (this occurred when CPU temperature reached +70°C up to +100°C). Components used for iMX8 Base Boards were only rated from 0°C to +85°C operating temperature range.<br /> | Test description: The ambient temperature was gradually increasing (from 60°C up to 100°C) while CPU, Memory and peripheral stress tests were running. The moment when CPU frequency had decreased was used as a test threshold (this occurred when CPU temperature reached +70°C up to +100°C). Components used for iMX8 Base Boards were only rated from 0°C to +85°C operating temperature range.<br /> | ||

[[image:iMX8M Industrial Kit-Env chamber-Boards at 86°C.png|800px]] | [[image:iMX8M Industrial Kit-Env chamber-Boards at 86°C.png|800px]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=== Switch ON/OFF test – PASS === | === Switch ON/OFF test – PASS === | ||

Revision as of 16:13, 20 July 2022

On this page environmental stress testing results of iMX8M Industrial Development Kit are displayed. Detailed instructions how to setup boards are also shown.

Hardware configuration

All of the modules used standard specification except of the temperature ranges for the key components as described below:

- 1x iMX8M Industrial Development Kit in Max configuration

- i.MX 8M Quad 1.5GHz CPU - extended industrial temperature range (-40°C to +105°C)

- 4GB LPDDR4 Memory - extended industrial temperature range (-40°C to +105°C)

- eMMC 32GB - industrial temperature range (-40°C to +85°C)

- WiFi & Bluetooth - industrial temperature range (-40°C to +85°C)

- 1x iMX8M Industrial Development Kit in Pro configuration

- i.MX 8M Quad 1.5GHz CPU - extended industrial temperature range (-40°C to +105°C)

- 2GB LPDDR4 Memory - automotive temperature range (-40°C to +125°C)

- eMMC 16GB - industrial temperature range (-40°C to +85°C)

- WiFi & Bluetooth - industrial temperature range (-40°C to +85°C)

- 1x iMX8M Industrial Development Kit in Pro Commercial configuration

- i.MX 8M Quad 1.5GHz CPU - extended industrial temperature range (0°C to +95°C)

- 2GB LPDDR4 Memory - automotive temperature range (-40°C to +125°C)

- eMMC 16GB - Commercial temperature range (-25°C to +85°C)

- WiFi & Bluetooth - industrial temperature range (-30°C to +85°C)

- 1x iMX8M Industrial Development Kit in Basic configuration

- i.MX 8M Quad 1.5GHz CPU - extended industrial temperature range (-40°C to +105°C)

- 1GB LPDDR4 Memory - industrial temperature range (-40°C to +95°C)

- eMMC 8GB - industrial temperature range (-40°C to +85°C)

- WiFi & Bluetooth - industrial temperature range (-40°C to +85°C)

All of the tested modules used standard configuration of iMX8M Development Baseboard with extended temperature range (-20°C to +85°C). The majority of tested kits used a standard heatsink. This heatsink sized 25x25x25mm is included in every development kit package. Thus these measurements show the actual performance of web shop based configuration. One of the board was mounted with extra large heatsink and one of the board was mounted with standard heatsink plus Fan to test effect on performance.

The setup in the environmental chamber:

Test description

Four iMX8M Industrial Development Kits (one in Max configuration, one in Pro configuration, one in Pro Commercial configuration and one in Basic configuration) were running full peripheral test and stressed all the peripherals in different range of temperatures to check the reliability and stability of the firmware and hardware design.

Configuration, software and testing threads in details:

1x iMX8M Industrial Development Kit [No 7] in Max configuration peripheral stress testing

- 1 thread of extensive Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- copying a file from the first USB device to SD card and vice versa

- copying a file from the second USB device to SD card and vice versa

- pinging the host PC via Ethernet

- all the messages were printed out on the serial console through connected Micro USB cable

- firmware running from eMMC

- standard 25x25x25mm heatsink plus fan

1x iMX8M Industrial Development Kit [No 4B] in Pro configuration Memory stress testing

- 1 thread of extensive Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- copying a file from the first USB device to SD card and vice versa

- copying a file from the second USB device to SD card and vice versa

- pinging the host PC via Ethernet

- all the messages were printed out on the serial console through connected Micro USB cable

- firmware running from eMMC

- Extra large 48x48x16mm heatsink

1x iMX8M Industrial Development Kit [No 3] in Pro Commercial configuration Memory stress testing

- 1 thread of extensive Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- copying a file from the first USB device to SD card and vice versa

- copying a file from the second USB device to SD card and vice versa

- pinging the host PC via Ethernet

- all the messages were printed out on the serial console through connected Micro USB cable

- firmware running from eMMC

- standard 25x25x25mm heatsink

1x iMX8M Industrial Development Kit [No 2B] in Basic configuration peripheral stress testing

- 1 thread of extensive Memory stress test

- 1 thread of CPU stress test

- sending HDMI Output to external monitor

- copying a file from the first USB device to SD card and vice versa

- copying a file from the second USB device to SD card and vice versa

- pinging the host PC via Ethernet

- all the messages were printed out on the serial console through connected Micro USB cable

- firmware running from eMMC

- standard 25x25x25mm heatsink

USB flash devices were placed outside the environmental chamber. All the scripts running during the test and the board setup instructions can be found in section How to prepare the test.

Testing Results

The picture below shows the temperature profile during the whole testing process:

680px

Running the boards at -40°C – PASS

Test description: CPU, Memory and peripheral stress tests were running at -40°C. All the tested kits were working without errors during the whole time, even if some components used for iMX8M PRO QuadLite Commercial were only rated for temperature range between 0°C and +95°C. iMX8M Industrial Development Base Boards were running at this temperature with components certified only from 0°C to +85°C temperature range.

A closer image on the temperature chamber displaying the minimum temperature is shown below. These readouts are available on the display:

- the first number shows current temperature

- the second one set temperature

- the last two shows rerelative humidity. Humidity was not controlled during testing process.

Running the kits at high temperatures (from +60°C to +100°C) – PASS

Test description: The ambient temperature was gradually increasing (from 60°C up to 100°C) while CPU, Memory and peripheral stress tests were running. The moment when CPU frequency had decreased was used as a test threshold (this occurred when CPU temperature reached +70°C up to +100°C). Components used for iMX8 Base Boards were only rated from 0°C to +85°C operating temperature range.

800px

Switch ON/OFF test – PASS

Test description: At temperatures from -30°C to -40°C the boards were switched OFF, left OFF for at least 5 minutes (to cool down completely) and then switched ON to see if they boot up without problems. Once booted up into Linux, the boards were turned off again. All of the tested boards booted up successfully. This test was performed 3 times at -30°C, -35°C and -40°C temperatures.

Cooling performance at high temperatures

Test description: As mentioned above, different heatsinks and enclosures were utilized in order to compare the cooling abilities. All these tests were performed with Max version which generate the most heat by itself. All setup reached temperature +85°C in the chamber while still successfully running. The board in the enclosure with the biggest height and cooling fins on the top size reached +100°C.

|

|

PC setup

During the test DHCP and FTP servers were utilised. The PC was also used during Ethernet ping test while controlling all the boards through SSH and serial console sessions. The control computer was running Windows 7 operating system.

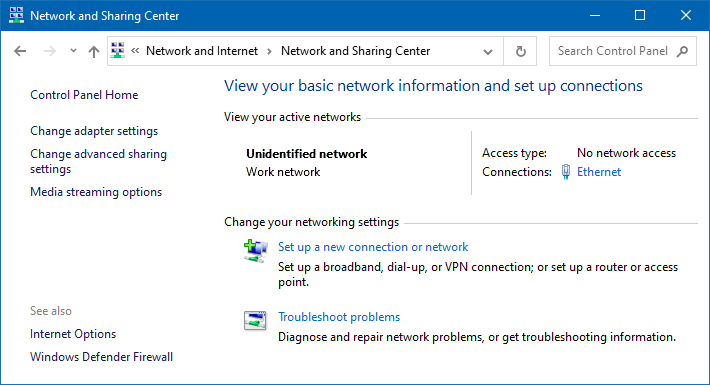

Setting the network

Disable firewall (PC will not be connected to the Internet) and setup a static IP address: Press Windows button -> go to Control Panel -> Network and Internet -> Network and Sharing Center -> Change adapter settings (on the right side in the bar) -> double click on Local Area Connection -> Properties -> In the tab Networking go to Internet Protocol Version 4 (TCP/IPv4) -> type the static IP address and subnet mask as shown below:

Enabling sharing

iMX6 TinyRex Development kits and the control PC are connected via Gigabit Ethernet switch. To ensure correct IP address assignment, turn on the PC first, connect it with the switch and only after that turn the switch on. To be able to download the files from the FTP server, sharing option need to be enabled first. This can be done by setting up the network as a work network. Sharing can be enabled in Control Panel -> Network and Internet -> Network and Sharing Center -> Click to Choose homegroup and sharing options:

Setting up the TFTP and DHCP servers

Tftpd32 software supports both TFTP and DHCP server options. For more details about DHCP configuration, follow the screenshots below:

SSH and Serial consoles

To control iMX6 TinyRex Development Kits, one TeraTerm serial console was opened per board. SSH clients were used to read temperature. For the boards with the peripheral test, an extra SSH client was established to be able to spot possible errors or warnings if occurred.

The setup of the environmental chamber cables and out-of-chamber equipment:

Preparing the test

Boot device and software

SD card was selected as a booting device for all the boards. U-Boot settings were not adjusted as the default configuration was used. The only change compared to standard software package was running a multimedia filesystem. To prepare a fresh SD card follow these instructions. Here is an example of creating a SD card suitable for Max configuration:

git clone https://github.com/voipac/imx6tinyrex_bin_linux cd imx6tinyrex_bin_linux/ sudo ./fsl-sdcard-partition.sh -max /dev/mmcblk0

Downloading stress test

Stressapptest package was selected to check CPU and memory integrity. Placing this file into the same directory where the testing script will be stored is important:

wget http://downloads.voipac.com/files/iMX6_TinyRex_Development_Kit/module/documents/Environmental_chamber_testing/stressapptest

Setup the cron

To be able to check the CPU temperature every minute a new cron job was setup. For Ubuntu file systems postfix package installation is required:

sudo apt-get install postfix

To setup a cron tab, the file containing all cron jobs needs to be altered. Before running the crontab for the first time, selecting a text editor is required:

sudo crontab -e

Paste the following line to the end of the cron list file. The output time format will be set the same as for stressapptest. Cron job performs a current CPU temperature readout and the data are saved in the log file. The log format was selected identical to the one used by stressapptest package:

* * * * * { echo -n $(date +%Y/%m/%d-%T); echo -n "("; echo -n $(date +%Z); echo -n ") "; cat /sys/devices/virtual/thermal/thermal_zone0/temp; } >> ~/testing-env-chamber/cpu-temp.log

Note: The percent sign '%' has a special purpose in the cron file. As this sign is needed to write the date formats, the backslash is required to be placed before the percent sign: '\%'.

Setting up the date

If the master PC is equipped with a timeserver, server date and time can be automatically obtained using this Linux feature:

ntpdate 192.168.0.2

Time and date can also be set up manually (use format MMDDhhmmYYYY e.g. 07th of July 2016 4:27 pm):

date 071116272016

Setup the CPU temperature printout

Open one SSH client per board where CPU temperature will be shown. Tail command is utilized to display the last part of the log file, which is filled up as the CRON job outputs the current readouts:

tail -F cpu-temp-measuring.log

Error checking during peripheral test

To make sure tests are running smoothly, potential errors can be detected by opening another SSH session:

tail -f env-chamber-testing.log | grep -i "error"

Play video file for peripheral test

To be able to test HDMI Input during the peripheral testing, a video file was played from boards which were running memory stress tests only. Infinite loop is opened in another SSH session:

while [ true ]; do gst-play-1.0 /media/ploughing.mp4; done

Start CPU and memory stress test

Navigate into the directory, where stressapptest feature and test are stored.

Stress command for Max configuration:

./stressapptest -s 600000 -M 1000 -m 4 -C 4 -W -l ~/env-chamber-testing/stressapptest.log --printsec 100

Stress command for Pro configuration:

./stressapptest -s 600000 -M 700 -m 2 -C 2 -W -l ~/env-chamber-testing/stressapptest.log --printsec 100

Stress command for Basic configuration:

./stressapptest -s 600000 -M 150 -m 1 -C 1 -W -l ~/env-chamber-testing/stressapptest.log --printsec 100

Start peripheral test

Before the test start it is a good practice to make sure that all the devices were plugged in successfully. To find out where the devices were mounted following command can be used:

fdisk -l

The testing script uses multiple variables to specify its operation. As the first parameter board configuration is used (-max, -pro or -basic). As other parameters device names

are written in the following order: the first USB stick, the second USB, SD card and SATA drive (if used). All logs are stored into a single file.

Starting peripheral test for Max configuration:

./imx6-tinyrex-v1i1-peripheral-test.sh -max sdb1 sdc1 mmcblk2p2 sda2 2>&1 | tee -i trx-env-chamber-testing.log

Starting peripheral test for Pro configuration:

./imx6-tinyrex-v1i1-peripheral-test.sh -pro sdb1 sdc1 mmcblk2p2 sda1 2>&1 | tee -i trx-env-chamber-testing.log

Starting peripheral test for Basic configuration:

./imx6-tinyrex-v1i1-peripheral-test.sh -basic sda1 sdb1 mmcblk2p2 2>&1 | tee -i trx-env-chamber-testing.log

The complete script can be found in the download section or down below:

#!/bin/sh

# iMX8MQ environmental chamber peripheral test

mountDevice() {

mkdir -p "/media/$2"

mount /dev/$1 /media/$2

cat /proc/mounts | grep -F "/dev/$1 /media/$2"

if [ "$?" -eq "0" ]; then

echo "$2 mounted"

else

echo "$2 not mounted"; exit 2

fi

}

# prepare files

cd ~/

mkdir -p env-chamber-testing/

cd env-chamber-testing/

touch env-chamber-testing.log

touch cpu-temp.log

basic=0

pro=0

max=0

case $1 in

-basic) basic=1 ;;

-pro) pro=1 ;;

-max) max=1 ;;

*)

esac

# mount devices

mountDevice $2 usb0

mountDevice $3 usb1

mountDevice $4 mmc0

updateLogFiles() {

# obtain board ID from IP address - be sure addresses are allocated based on MAC

boardID=$(/sbin/ip -o -4 addr list eth0 | awk '{print $4}' | cut -d/ -f1 | cut -d'.' -f4 | cut -d'2' -f2);

# be sure time server is running on DHCP server

currentTime=`date +%Y-%m-%d.%H:%M`

mv env-chamber-testing.log trx-board-$boardID-env-chamber.log.$currentTime

mv cpu-temp.log trx-board-$boardID-env-cpu-temp.log.$currentTime

}

finish_test_now() {

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Ctrl+C Detected: End of the test"

precced=0;

#kill -INT $vid_pid $str_pid $log_pid;

sleep 3;

test_status=`cat env-chamber-testing.log | grep -i "error" | grep -v -e "0 errors" -e "no corrected errors"`

if [ -z "$test_status" ]

then

echo "*********TEST PASS*********"

else

echo "*********TEST FAIL*********"

echo "List of detected errors:"

cat env-chamber-testing.log | grep -i "error" | grep -v -e "0 errors" -e "no corrected errors" -e "List of detected errors:"

fi

updateLogFiles

exit;

}

# kill all processes if Ctrl+C is detected

trap finish_test_now 2

# play a video stream from HDMI input - testing also HDMI output

gst-launch-1.0 -q imxv4l2src ! autovideosink &

# stressapptest - one thread CPU, one thread memory, sata thread (if possible)

if [ "${basic}" -eq "1" ]; then

stress-ng --cpu 2 --vm 4 &

str_pid=$!

fi

if [ "${pro}" -eq "1" ]; then

stress-ng --cpu 4 --vm 4 &

str_pid=$!

fi

if [ "${max}" -eq "1" ]; then

stress-ng --cpu 4 --vm 4 &

str_pid=$!

fi

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Starting stressapptest with PID: " $str_pid

proceed=1

# create test files

file1_path=`mktemp`

file2_path=`mktemp`

file1=`basename $file1_path`

file2=`basename $file2_path`

dd if=/dev/urandom of=$file1_path bs=1024 count=10000

dd if=/dev/urandom of=$file2_path bs=1024 count=10000

cp1_from="/media/mmc0/"

cp1_to="/media/usb0/"

cp2_from="/media/usb0/"

cp2_to="/media/usb1/"

#copy files in case they are missing

cp $file1_path $cp1_from

cp $file1_path $cp1_to

cp $file2_path $cp2_from

cp $file2_path $cp2_to

while [ $proceed -eq 1 ]

do

ping -q -c1 127.0.0.1 >> env-chamber-testing.log

if [ $? -ne 0 ]

then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Ping failed"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Ping OK"

fi

cp1_done=`ps | grep $cp1_pid | grep cp`

if [ -z "$cp1_done" ]; then # copy finished

if cmp -s $cp1_from$file1 $cp1_to$file1; then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) PASS: Copying file from $cp1_from to $cp1_to successful"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Difference between files on $cp1_from and $cp1_to detected"

fi

cp1_temp=$cp1_from # swap destinations

cp1_from=$cp1_to

cp1_to=$cp1_temp

rm $cp1_to$file1 # remove destination file

cp $cp1_from$file1 $cp1_to$file1 &

cp1_pid=$!

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Started copying file from $cp1_from to $cp1_to"

fi

cp2_done=`ps | grep $cp2_pid | grep cp`

if [ -z "$cp2_done" ]; then # copy finished

if cmp -s $cp2_from$file2 $cp2_to$file2; then

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) PASS: Copying file from $cp2_from to $cp2_to successful"

else

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) ERROR: Difference between files on $cp2_from and $cp2_to detected"

fi

cp2_temp=$cp2_from # swap destinations

cp2_from=$cp2_to

cp2_to=$cp2_temp

rm $cp2_to$file2 # remove destination file

cp $cp2_from$file2 $cp2_to$file2 &

cp2_pid=$!

echo "$(date +\%Y/\%m/\%d-\%T)($(date +\%Z)) Started copying file from $cp2_from to $cp2_to"

fi

done